| Availability: | |

|---|---|

| Quantity: | |

HUAYAN

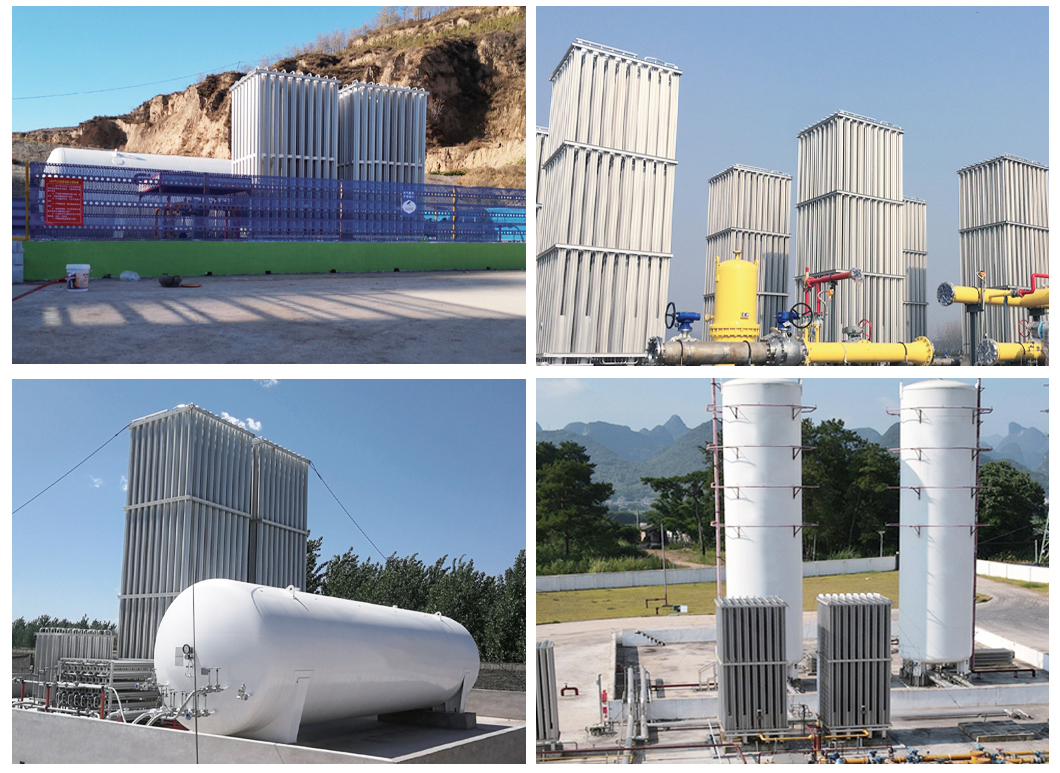

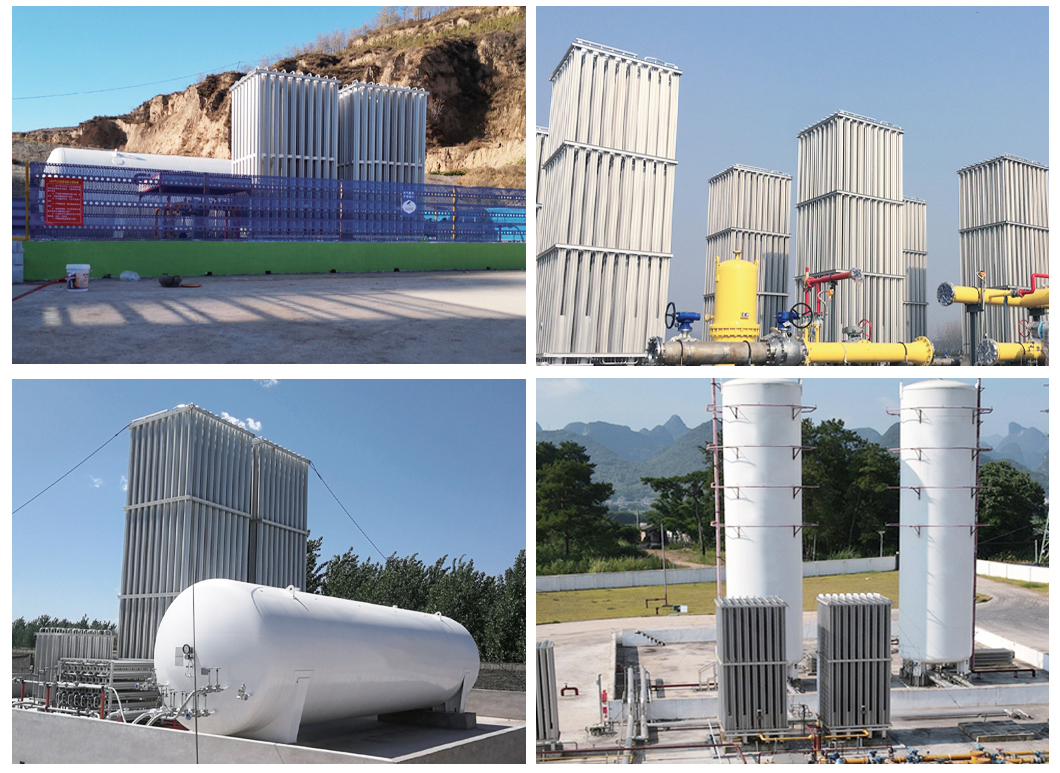

The working principle of LNG gasification station is to convert the LNG liquid in the LNG storage tank or low-temperature insulated bottle group into gas at normal pressure by absorbing heat through air-temperature vaporizer, and then adjust the pressure through the system until the pressure of the user's equipment is met, and then measure and odorize it, and transport it to the natural gas station and boiler for residents and industrial production. It can also be used as urban peak load shaving equipment and backup equipment. The main equipment includes storage tanks, air-temperature vaporizers, unloading boosters, storage tank boosters, water bath vaporizers, pressure regulating and metering skids and PLC control system related supporting equipment.

Main functions

LNG gasification and reheating functions

LNG pressure regulation, voltage stabilization, and pressure relief protection functions

Filtering, metering, odorization, etc.

Emergency shutoff function, safer to use

Liquid level monitoring function

This series of vaporizers is a kind of high-efficiency and energy-saving heat exchange equipment that uses natural convection of air to heat the low-temperature liquid (LO2, LN2, LAr, LNG, LCO2, LC2H4, LPG) in the heat exchange tube to completely evaporate it into gas. Its main advantages are:

No energy consumption, no pollution, green and environmentally friendly, easy installation and maintenance.

Special aluminum heat exchange, high efficiency, lightweight design, long service life.

Special medium 200 ultra-large diameter special aluminum heat exchange tube, extremely fast defrosting speed, effective internal fin structure, greatly improve the heat exchange effect of the heat exchange tube. The "bridge" type connection element is beautiful and generous, and eliminates the stress caused by thermal expansion and contraction of various parts during operation.

Special anti-oxidation treatment process for the surface of the heat exchange tube.

Optimize the process design to reduce the pressure drop to a minimum, without bias flow phenomenon, and ensure that the flow rate is controlled within a safe range.

Sufficient design margin. Advanced high-pressure pipe composite technology allows the pressurized pipe to be 100% fully in contact with the heat exchange tube, ensuring heat exchange efficiency.

All vaporizers are cleaned and manufactured in full accordance with oxygen service standards, making them safer to use.

Design conditions: temperature -10°C, relative humidity 70%, and vaporization volume for continuous use for 8-12 hours.

Description: Factors affecting vaporization volume include: working cycle, ambient temperature, humidity, altitude, wind, light, operating pressure, adjacent buildings, etc.

Applicable media: LO2, LN2, LAr, LNG, LCO2, LC2H4, LPG

All products can be customized as required please contact us

Project | Parameter | Remarks |

Medium | LOX / LIN / LAR / LNG / CO₂ etc | optional |

Rated Capacity | 500 Nm³/h ~ 3000 Nm³/h | Design according to requirements |

Working Pressure | 0.8 MPa ~ 3.0 MPa | Typical value: 2.5 MPa |

Inlet Pressure | 0.6 MPa ~ 2.5 MPa | Output from storage tank |

Outlet Pressure | 0.5 MPa ~ 2.3 MPa | Depending on the system |

Design Temperature | -196℃ ~ +60℃ | Suitable for low-temperature working conditions |

Heat Exchange Type | Natural air convection | No energy consumption, green and environmentally friendly |

Material | Specialized aluminum alloy | High thermal conductivity and low temperature resistance |

Heat Exchange Area | Determined by design | ㎡ |

Vaporization Efficiency | ≥98% | Under standard operating conditions |

Installation | Vertical/modular combination | ground installation |

Ambient Conditions | Environmental temperature ≥ 5 ℃ | Suggest good natural ventilation |

ABOUT US

Jiangsu Huayan International Trade Co., Ltd. was established in 2005 and is headquartered in Xuzhou, Jiangsu Province, China. It is a leading integrated transportation solution provider integrating R&D, production and trade. Covering an area of 222,000 square meters, the company uses advanced automation equipment, a professional R&D team and cutting-edge manufacturing technology to provide high-quality special transportation equipment, including gas equipment (hydraulic modular trailers,gas pipeline slide container trailers, powder/liquid tankers and a full range of semi-trailers(heavy-duty low-bed,) for energy, hazardous chemical transportation and engineering logistics. Its core hydraulic system is compatible with international brands such as Goldhofer and Scheuerle, ensuring compliance with global technical standards. The company has more than 20 years of export experience and serves more than 30 countries including Peru, India, Russia and Brazil. The company has passed ISO9001, ASME, ADR certification, has a R&D team of more than 60 people (including 8 senior engineers), and has achieved a 100% order delivery rate through ERP+MES digital management. The company is committed to sustainable development, adhering to the values of innovation, quality, expertise and mutual benefit, and providing safe, efficient and environmentally friendly transportation solutions worldwide.

Patent certificate

Our company's products have passed IS09001, 14001 and CE certificates, and we can alsoprovide relevant certificates that meet customer national requirements

Cooperative Brand

Our Customers

Core Technology Team

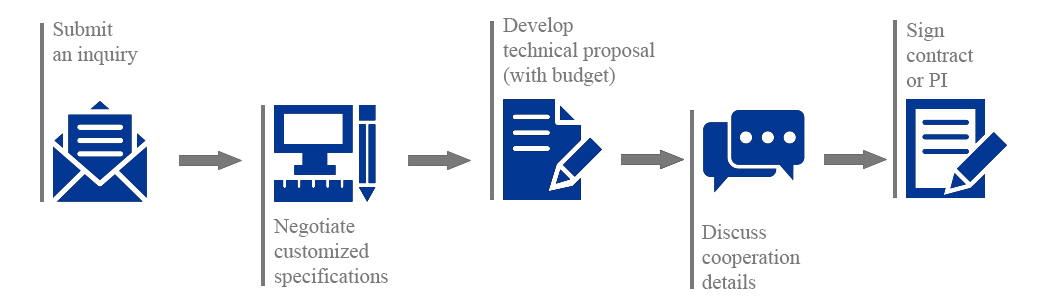

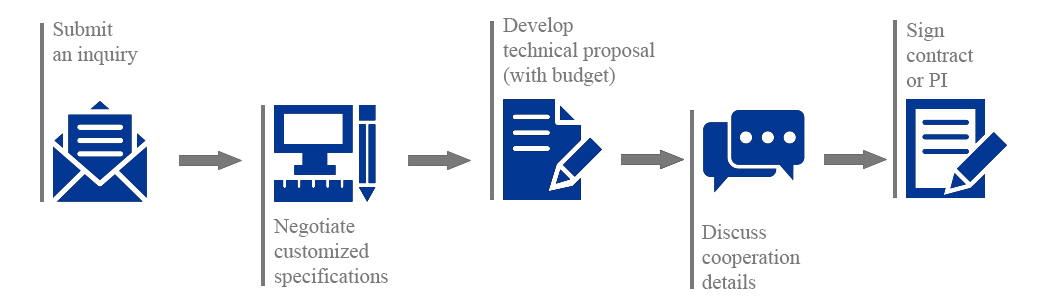

Cooperation Process

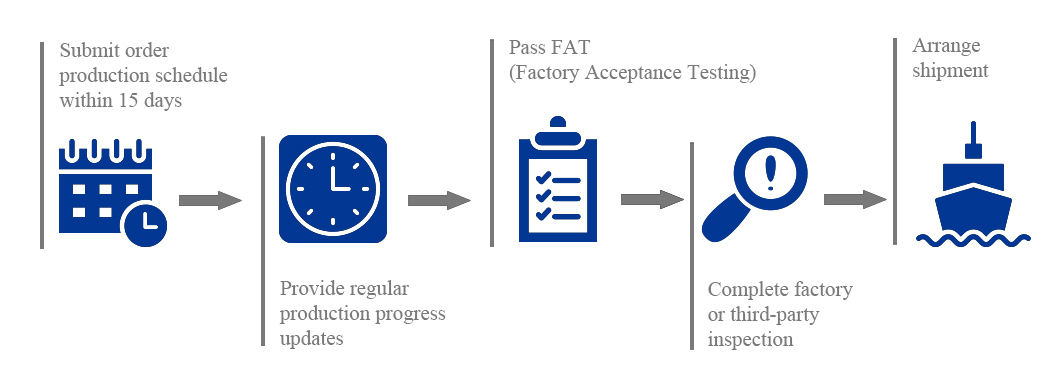

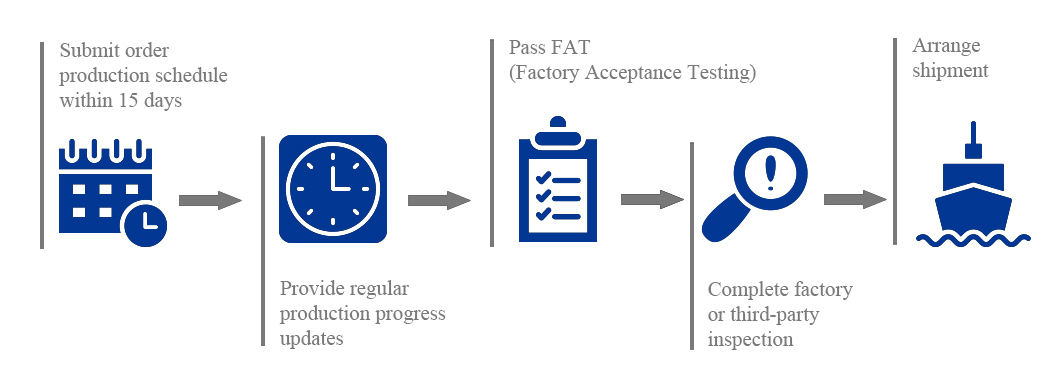

After order

Delivery capability

Our company will prepare a delivery schedule for your project, and we have good logisticscapabilities to provide you with domestic and international logistics delivery capabilities in China.

FAQ

1. What are the main components of a CNG long tube trailer?

1. Trailer,

2. framework,

3. large-cubage seamless steel cylinders,

4. for safety cabin,

5. back operation cabin.

You will own a professional team in China by cooperating with HUAYAN

5. What's The Time For Delivery & Arrival?

If the Standard Model We Have In Stock Can Ship It Out Within 10 -15 days After Payment.

If It Customizes, Ordinary Cases In 15-20 days Can Be Finished For Shipment.

The working principle of LNG gasification station is to convert the LNG liquid in the LNG storage tank or low-temperature insulated bottle group into gas at normal pressure by absorbing heat through air-temperature vaporizer, and then adjust the pressure through the system until the pressure of the user's equipment is met, and then measure and odorize it, and transport it to the natural gas station and boiler for residents and industrial production. It can also be used as urban peak load shaving equipment and backup equipment. The main equipment includes storage tanks, air-temperature vaporizers, unloading boosters, storage tank boosters, water bath vaporizers, pressure regulating and metering skids and PLC control system related supporting equipment.

Main functions

LNG gasification and reheating functions

LNG pressure regulation, voltage stabilization, and pressure relief protection functions

Filtering, metering, odorization, etc.

Emergency shutoff function, safer to use

Liquid level monitoring function

This series of vaporizers is a kind of high-efficiency and energy-saving heat exchange equipment that uses natural convection of air to heat the low-temperature liquid (LO2, LN2, LAr, LNG, LCO2, LC2H4, LPG) in the heat exchange tube to completely evaporate it into gas. Its main advantages are:

No energy consumption, no pollution, green and environmentally friendly, easy installation and maintenance.

Special aluminum heat exchange, high efficiency, lightweight design, long service life.

Special medium 200 ultra-large diameter special aluminum heat exchange tube, extremely fast defrosting speed, effective internal fin structure, greatly improve the heat exchange effect of the heat exchange tube. The "bridge" type connection element is beautiful and generous, and eliminates the stress caused by thermal expansion and contraction of various parts during operation.

Special anti-oxidation treatment process for the surface of the heat exchange tube.

Optimize the process design to reduce the pressure drop to a minimum, without bias flow phenomenon, and ensure that the flow rate is controlled within a safe range.

Sufficient design margin. Advanced high-pressure pipe composite technology allows the pressurized pipe to be 100% fully in contact with the heat exchange tube, ensuring heat exchange efficiency.

All vaporizers are cleaned and manufactured in full accordance with oxygen service standards, making them safer to use.

Design conditions: temperature -10°C, relative humidity 70%, and vaporization volume for continuous use for 8-12 hours.

Description: Factors affecting vaporization volume include: working cycle, ambient temperature, humidity, altitude, wind, light, operating pressure, adjacent buildings, etc.

Applicable media: LO2, LN2, LAr, LNG, LCO2, LC2H4, LPG

All products can be customized as required please contact us

Project | Parameter | Remarks |

Medium | LOX / LIN / LAR / LNG / CO₂ etc | optional |

Rated Capacity | 500 Nm³/h ~ 3000 Nm³/h | Design according to requirements |

Working Pressure | 0.8 MPa ~ 3.0 MPa | Typical value: 2.5 MPa |

Inlet Pressure | 0.6 MPa ~ 2.5 MPa | Output from storage tank |

Outlet Pressure | 0.5 MPa ~ 2.3 MPa | Depending on the system |

Design Temperature | -196℃ ~ +60℃ | Suitable for low-temperature working conditions |

Heat Exchange Type | Natural air convection | No energy consumption, green and environmentally friendly |

Material | Specialized aluminum alloy | High thermal conductivity and low temperature resistance |

Heat Exchange Area | Determined by design | ㎡ |

Vaporization Efficiency | ≥98% | Under standard operating conditions |

Installation | Vertical/modular combination | ground installation |

Ambient Conditions | Environmental temperature ≥ 5 ℃ | Suggest good natural ventilation |

ABOUT US

Jiangsu Huayan International Trade Co., Ltd. was established in 2005 and is headquartered in Xuzhou, Jiangsu Province, China. It is a leading integrated transportation solution provider integrating R&D, production and trade. Covering an area of 222,000 square meters, the company uses advanced automation equipment, a professional R&D team and cutting-edge manufacturing technology to provide high-quality special transportation equipment, including gas equipment (hydraulic modular trailers,gas pipeline slide container trailers, powder/liquid tankers and a full range of semi-trailers(heavy-duty low-bed,) for energy, hazardous chemical transportation and engineering logistics. Its core hydraulic system is compatible with international brands such as Goldhofer and Scheuerle, ensuring compliance with global technical standards. The company has more than 20 years of export experience and serves more than 30 countries including Peru, India, Russia and Brazil. The company has passed ISO9001, ASME, ADR certification, has a R&D team of more than 60 people (including 8 senior engineers), and has achieved a 100% order delivery rate through ERP+MES digital management. The company is committed to sustainable development, adhering to the values of innovation, quality, expertise and mutual benefit, and providing safe, efficient and environmentally friendly transportation solutions worldwide.

Patent certificate

Our company's products have passed IS09001, 14001 and CE certificates, and we can alsoprovide relevant certificates that meet customer national requirements

Cooperative Brand

Our Customers

Core Technology Team

Cooperation Process

After order

Delivery capability

Our company will prepare a delivery schedule for your project, and we have good logisticscapabilities to provide you with domestic and international logistics delivery capabilities in China.

FAQ

1. What are the main components of a CNG long tube trailer?

1. Trailer,

2. framework,

3. large-cubage seamless steel cylinders,

4. for safety cabin,

5. back operation cabin.

You will own a professional team in China by cooperating with HUAYAN

5. What's The Time For Delivery & Arrival?

If the Standard Model We Have In Stock Can Ship It Out Within 10 -15 days After Payment.

If It Customizes, Ordinary Cases In 15-20 days Can Be Finished For Shipment.