| Availability: | |

|---|---|

| Quantity: | |

HUAYAN

Cryogenic storage tank description

Cryogenic storage tanks which are designed and manufactured by HUAYAN are strictly in accordance with national standards, such as ASME, CE, GB150, GB18442, etc. These tanks with various working pressure and spec can be widely used in the storage and usage of liquefied natural gas, oxygen, nitrogen, argon, carbon dioxide, ethylene, etc. For Micro-tank, the volume ranges from 1m3~7.5m3, working pressure ranges from 1.6Mpa~3.6Mpa. For the standardized cryogenic tank, volume ranges from 5m3~150m3, working pressure ranges from 0.8Mpa~1.6Mpa.

The cryogenic storage tanks have adopted special high vacuumed thermal insulation technology, which ensures excellent thermal insulation performance, enduring vacuum maintenance, lower use-cost. Modularized pipeline design and advanced configuration highly improves the performance and endurance, decreases the maintenance cost, enhances you competitive advantage.

It is capable of customizing cryogenic storage tanks with a volume up to 200m3 or even higher in accordance with customers' requests, and we are able to supply various equipment such as vaporizers, pressure regulating & metering skids, buffer tanks, combined pressure regulating device, (PCM)PLC control system( unattended operation), EPC turnkey projects.

Core advantages of cryogenic storage tanks

High-efficiency insulation · Low evaporation

Vacuum multi-layer insulation technology (such as vacuum powder/winding) effectively blocks heat conduction and maintains long-term stability of media such as LNG (-162ºC).

Daily evaporation rate ≤0.3%, extremely low medium loss, and controllable operating costs.

Multiple safety protections

Anti-leakage design: double-layer closed structure (liner + vacuum interlayer) + safety valve/bursting disc to eliminate overpressure and leakage risks.

Strong weather resistance: stainless steel/aluminum alloy material, low temperature resistance, corrosion resistance, in line with ASME/GB standards, and adaptable to complex environments.

Large capacity · low cost

The capacity of a single tank is 150m³+, meeting the large-scale storage needs of industrial energy.

The liquefied volume is reduced by 600 times, saving storage and transportation space, and reducing the overall cost by more than 40%.

Flexible adaptation · customization

Multiple forms are available: vertical/horizontal/mobile (tank truck), suitable for gas stations, chemical plants and other scenes.

Non-standard customization: support on-demand adjustment of size, pressure and interface to meet special working conditions.

Our factory has a professional technical team and advanced welding technology. We have engaged in R&D of Normal Temperature Storage & Transportation Equipment, Cryogenic Storage & Transportation Equipment, Chemical Equipment and other types of Energy/Chemical Storage & Transportation Equipment, and Oil & Gas Industry Pipeline EPC Services since 2005. Owing to the advanced technology, we guarantee the highest quality by controlling and supervising every detail. LPG storage and transportation equipment has been distributed to more than 40 countries and areas in America, the Middle East, Southeast Asia, Northeast Asia, and Africa.

All products can be customized as required please contact us

| LNG Cryogenic Storage Tank Technical Specification | |||||||

| Geometric Volume | Geometric Volume | Work Pressure (MPa) | Liquid Gases Weight (kg) | Tare Weight (kg) | Inner vessel | Outer vessel | Overall Dimensions (mm) |

| Vertical | 10 | ≤0.80 | 3829 | 4012 | SS30408 | SS30408/Q345R | 5800*2112*2196 |

| ≤1.60 | 4112 | ||||||

| ≤2.30 | 4527 | ||||||

| ≤3.45 | 5360 | ||||||

| 20 | ≤0.80 | 7916 | 7441 | SS30408 | SS30408/Q345R | 10320*2196*2196 | |

| ≤1.60 | 7921 | ||||||

| ≤2.30 | 8696 | ||||||

| ≤3.45 | 10251 | ||||||

| 50 | ≤0.80 | 20235 | 14221 | SS30408 | SS30408/Q345R | 5975*2135*2077 | |

| ≤1.60 | 16860 | ||||||

| Horizontal | 10 | ≤0.80 | 4043 | 4112 | SS30408 | SS30408/Q345R | 6080*2362*2200 |

| ≤1.60 | 4203 | ||||||

| ≤2.30 | 4679 | ||||||

| ≤3.45 | 5634 | ||||||

| 20 | ≤0.80 | 7915 | 5238 | SS30408 | SS30408/Q345R | 10495*2362*2200 | |

| ≤1.60 | 5329 | ||||||

| ≤2.30 | 6182 | ||||||

| ≤3.45 | 7894 | ||||||

| 50 | ≤0.80 | 20235 | 16396 | SS30408 | SS30408/Q345R | 11200*3200*3500 | |

| ≤1.59 | 19587 | ||||||

| Note: The above technical parameters may be changed without prior notice due to modification and development. If there is any change, please refer to the confirmed drawing. | |||||||

ABOUT US

Jiangsu Huayan International Trade Co., Ltd. was established in 2005 and is headquartered in Xuzhou, Jiangsu Province, China. It is a leading integrated transportation solution provider integrating R&D, production and trade. Covering an area of 222,000 square meters, the company uses advanced automation equipment, a professional R&D team and cutting-edge manufacturing technology to provide high-quality special transportation equipment, including gas equipment (hydraulic modular trailers,gas pipeline slide container trailers, powder/liquid tankers and a full range of semi-trailers(heavy-duty low-bed,) for energy, hazardous chemical transportation and engineering logistics. Its core hydraulic system is compatible with international brands such as Goldhofer and Scheuerle, ensuring compliance with global technical standards. The company has more than 20 years of export experience and serves more than 30 countries including Peru, India, Russia and Brazil. The company has passed ISO9001, ASME, ADR certification, has a R&D team of more than 60 people (including 8 senior engineers), and has achieved a 100% order delivery rate through ERP+MES digital management. The company is committed to sustainable development, adhering to the values of innovation, quality, expertise and mutual benefit, and providing safe, efficient and environmentally friendly transportation solutions worldwide.

Patent certificate

Our company's products have passed IS09001, 14001 and CE certificates, and we can alsoprovide relevant certificates that meet customer national requirements

Cooperative Brand

Our Customers

Core Technology Team

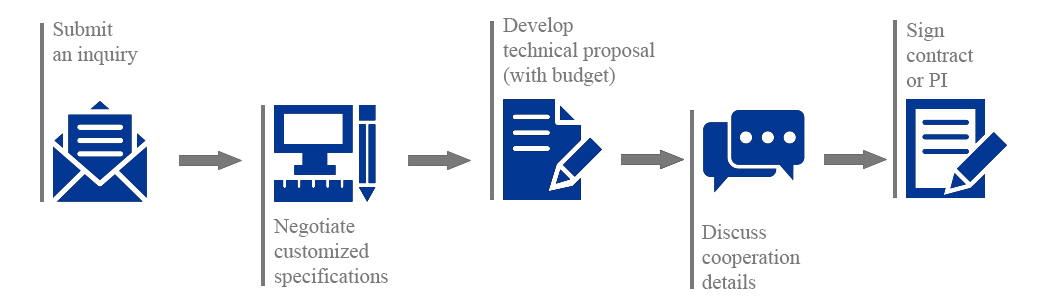

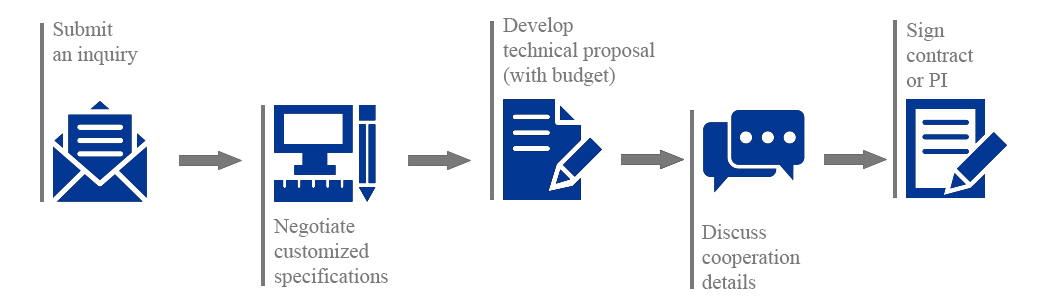

Cooperation Process

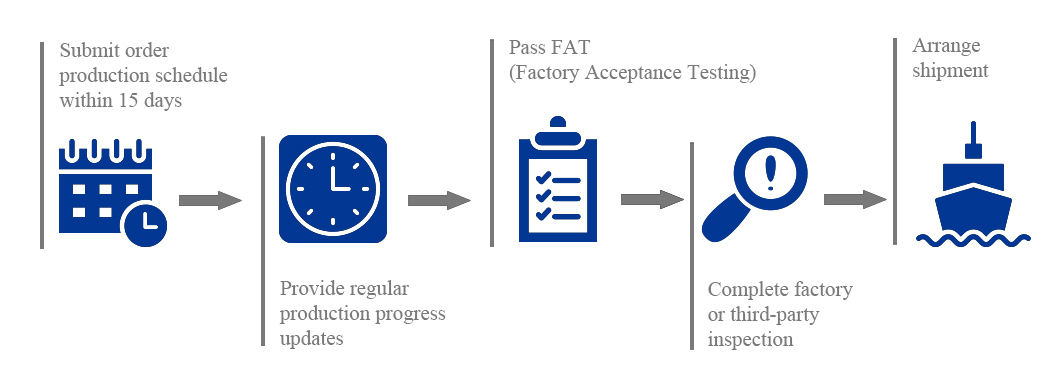

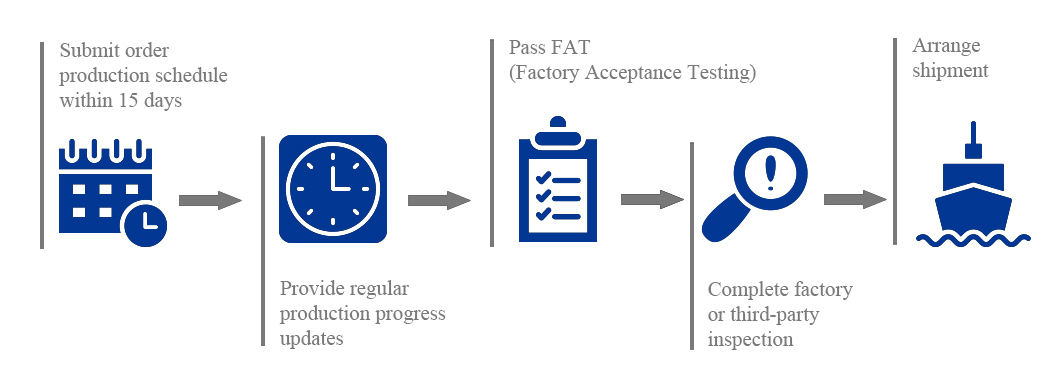

After order

Delivery capability

Our company will prepare a delivery schedule for your project, and we have good logisticscapabilities to provide you with domestic and international logistics delivery capabilities in China.

FAQ

1. What is your daily production capacity?

Our production capacity every year is 80~100 units.

We specialize in offering a wide range of cryogenic storage tanks, such as LCO2, LAr, LNG, LPG, LOX and so on .

3. May I have the best price from you?

5. What's The Time For Delivery & Arrival?

If the standard models are in stock, then we can ship them out within 30 days after payment.

If customized, 40 days can be ready for shipment.

Cryogenic storage tank description

Cryogenic storage tanks which are designed and manufactured by HUAYAN are strictly in accordance with national standards, such as ASME, CE, GB150, GB18442, etc. These tanks with various working pressure and spec can be widely used in the storage and usage of liquefied natural gas, oxygen, nitrogen, argon, carbon dioxide, ethylene, etc. For Micro-tank, the volume ranges from 1m3~7.5m3, working pressure ranges from 1.6Mpa~3.6Mpa. For the standardized cryogenic tank, volume ranges from 5m3~150m3, working pressure ranges from 0.8Mpa~1.6Mpa.

The cryogenic storage tanks have adopted special high vacuumed thermal insulation technology, which ensures excellent thermal insulation performance, enduring vacuum maintenance, lower use-cost. Modularized pipeline design and advanced configuration highly improves the performance and endurance, decreases the maintenance cost, enhances you competitive advantage.

It is capable of customizing cryogenic storage tanks with a volume up to 200m3 or even higher in accordance with customers' requests, and we are able to supply various equipment such as vaporizers, pressure regulating & metering skids, buffer tanks, combined pressure regulating device, (PCM)PLC control system( unattended operation), EPC turnkey projects.

Core advantages of cryogenic storage tanks

High-efficiency insulation · Low evaporation

Vacuum multi-layer insulation technology (such as vacuum powder/winding) effectively blocks heat conduction and maintains long-term stability of media such as LNG (-162ºC).

Daily evaporation rate ≤0.3%, extremely low medium loss, and controllable operating costs.

Multiple safety protections

Anti-leakage design: double-layer closed structure (liner + vacuum interlayer) + safety valve/bursting disc to eliminate overpressure and leakage risks.

Strong weather resistance: stainless steel/aluminum alloy material, low temperature resistance, corrosion resistance, in line with ASME/GB standards, and adaptable to complex environments.

Large capacity · low cost

The capacity of a single tank is 150m³+, meeting the large-scale storage needs of industrial energy.

The liquefied volume is reduced by 600 times, saving storage and transportation space, and reducing the overall cost by more than 40%.

Flexible adaptation · customization

Multiple forms are available: vertical/horizontal/mobile (tank truck), suitable for gas stations, chemical plants and other scenes.

Non-standard customization: support on-demand adjustment of size, pressure and interface to meet special working conditions.

Our factory has a professional technical team and advanced welding technology. We have engaged in R&D of Normal Temperature Storage & Transportation Equipment, Cryogenic Storage & Transportation Equipment, Chemical Equipment and other types of Energy/Chemical Storage & Transportation Equipment, and Oil & Gas Industry Pipeline EPC Services since 2005. Owing to the advanced technology, we guarantee the highest quality by controlling and supervising every detail. LPG storage and transportation equipment has been distributed to more than 40 countries and areas in America, the Middle East, Southeast Asia, Northeast Asia, and Africa.

All products can be customized as required please contact us

| LNG Cryogenic Storage Tank Technical Specification | |||||||

| Geometric Volume | Geometric Volume | Work Pressure (MPa) | Liquid Gases Weight (kg) | Tare Weight (kg) | Inner vessel | Outer vessel | Overall Dimensions (mm) |

| Vertical | 10 | ≤0.80 | 3829 | 4012 | SS30408 | SS30408/Q345R | 5800*2112*2196 |

| ≤1.60 | 4112 | ||||||

| ≤2.30 | 4527 | ||||||

| ≤3.45 | 5360 | ||||||

| 20 | ≤0.80 | 7916 | 7441 | SS30408 | SS30408/Q345R | 10320*2196*2196 | |

| ≤1.60 | 7921 | ||||||

| ≤2.30 | 8696 | ||||||

| ≤3.45 | 10251 | ||||||

| 50 | ≤0.80 | 20235 | 14221 | SS30408 | SS30408/Q345R | 5975*2135*2077 | |

| ≤1.60 | 16860 | ||||||

| Horizontal | 10 | ≤0.80 | 4043 | 4112 | SS30408 | SS30408/Q345R | 6080*2362*2200 |

| ≤1.60 | 4203 | ||||||

| ≤2.30 | 4679 | ||||||

| ≤3.45 | 5634 | ||||||

| 20 | ≤0.80 | 7915 | 5238 | SS30408 | SS30408/Q345R | 10495*2362*2200 | |

| ≤1.60 | 5329 | ||||||

| ≤2.30 | 6182 | ||||||

| ≤3.45 | 7894 | ||||||

| 50 | ≤0.80 | 20235 | 16396 | SS30408 | SS30408/Q345R | 11200*3200*3500 | |

| ≤1.59 | 19587 | ||||||

| Note: The above technical parameters may be changed without prior notice due to modification and development. If there is any change, please refer to the confirmed drawing. | |||||||

ABOUT US

Jiangsu Huayan International Trade Co., Ltd. was established in 2005 and is headquartered in Xuzhou, Jiangsu Province, China. It is a leading integrated transportation solution provider integrating R&D, production and trade. Covering an area of 222,000 square meters, the company uses advanced automation equipment, a professional R&D team and cutting-edge manufacturing technology to provide high-quality special transportation equipment, including gas equipment (hydraulic modular trailers,gas pipeline slide container trailers, powder/liquid tankers and a full range of semi-trailers(heavy-duty low-bed,) for energy, hazardous chemical transportation and engineering logistics. Its core hydraulic system is compatible with international brands such as Goldhofer and Scheuerle, ensuring compliance with global technical standards. The company has more than 20 years of export experience and serves more than 30 countries including Peru, India, Russia and Brazil. The company has passed ISO9001, ASME, ADR certification, has a R&D team of more than 60 people (including 8 senior engineers), and has achieved a 100% order delivery rate through ERP+MES digital management. The company is committed to sustainable development, adhering to the values of innovation, quality, expertise and mutual benefit, and providing safe, efficient and environmentally friendly transportation solutions worldwide.

Patent certificate

Our company's products have passed IS09001, 14001 and CE certificates, and we can alsoprovide relevant certificates that meet customer national requirements

Cooperative Brand

Our Customers

Core Technology Team

Cooperation Process

After order

Delivery capability

Our company will prepare a delivery schedule for your project, and we have good logisticscapabilities to provide you with domestic and international logistics delivery capabilities in China.

FAQ

1. What is your daily production capacity?

Our production capacity every year is 80~100 units.

We specialize in offering a wide range of cryogenic storage tanks, such as LCO2, LAr, LNG, LPG, LOX and so on .

3. May I have the best price from you?

5. What's The Time For Delivery & Arrival?

If the standard models are in stock, then we can ship them out within 30 days after payment.

If customized, 40 days can be ready for shipment.